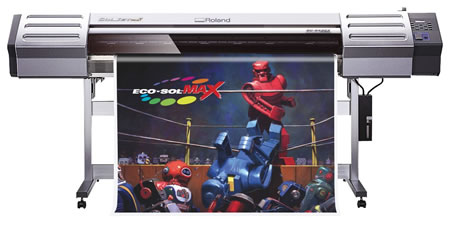

Press Release: Roland Introduces ECO-SOL MAX Ink

IRVINE, California, August 26, 2005 - Roland DGA

Corporation, a leading provider of wide-format inkjet printers and integrated

printer/cutters for the sign making, POP, exhibit, labels and vehicle graphics

markets, today announced new and improved ECO-SOL MAX ink. ECO-SOL MAX achieves

new levels of performance and represents a major step forward for ink

technology.

In addition to the company’s award-winning line

of inkjet printers and integrated printer/cutters, Roland has pioneered the

development of advanced inks that meet the highest standards for performance,

safety and durability, including the first pigment ink for wide-format inkjets.

In 2003, Roland broke new ground with the introduction of Eco-SOL INK, the

industry’s first eco-solvent ink and a safe, cost-effective alternative to

hard solvent inks.

ECO-SOL MAX builds on this advanced ink technology

with several enhancements including faster drying time, higher density, wider

color gamut, improved scratch resistance, and expanded uncoated media support.

In addition, ECO-SOL MAX is virtually odorless, contains no harmful VOCs, and

requires no special ventilation or environmental equipment.

"New ECO-SOL MAX ink is an exciting innovation for the

wide-format printing industry and a significant upgrade to Roland’s inkjet

line," said Barry Johnston, color products division manager, Roland DGA.

“ECO-SOL MAX has been refined to deliver unparalleled performance on a

broad range of media options. In addition to reducing production costs, these

enhancements expand the range of applications available to Roland inkjet

customers.”

Faster Drying Time

Featuring an improved drying time, ECO-SOL MAX

produces graphics that are dry to the touch after printing. This advantage

increases productivity and allows ECO-SOL MAX ink to perform with take-up roller

systems for long, unattended production runs, even in high-speed

mode.

Ideal for Outdoor Banner Production and Other Complex

Applications

For even greater durability, ECO-SOL MAX features

improved scratch resistance, critical to the production of outdoor banners and

other graphics that involve complex finishing techniques. For outdoor banners,

ECO-SOL MAX maintains image quality throughout the printing and finishing

processes including welding, sewing, and the attachment of grommets. With higher

ink density and wider color gamut, ECO-SOL MAX graphics reflect superb color

when viewed at a distance or close up.

ECO-SOL MAX Features

• Quick drying time – For improved

production speed

• Improved scratch resistance – For

increased durability and easy handling

• Wider color gamut – Delivers vivid,

precision printing across the color spectrum with expanded color gamut for reds,

blues and greens

• Virtually odorless – Ensures a highly

comfortable working environment

• Comprehensive media support - ICC profiles

are available for Roland’s full line of value-priced media including

uncoated options

• High-density color – Produces glossy

finish and vivid solid colors

• Durability – Graphics last up to

three years outdoors without lamination

• Eco-friendly – Gentle for users,

equipment and the environment

• Versatility - Ideally suited for both

indoor and outdoor applications

• Supports Lamination - Great for indoor

poster graphics and other applications

ECO-SOL MAX is available immediately from Roland and

is compatible with all PRO II V SOLJET™ and VersaCAMM® printers and

integrated printer/cutters.

Roland Inks and Media

Reflecting the company’s commitment to providing

complete solutions, Roland offers a comprehensive line of tested and certified

inks and media. Widely recognized for their performance and durability, Roland

inks include the company’s new ECO-SOL MAX ink featured in all VersaCAMM

and PRO II V SOLJET inkjets; Roland aqueous ink, available in both dye and

pigment options for Hi-Fi JET™ printers; and custom HeatWave®

sublimation ink, an option for VersaCAMM integrated printer/cutters and the

SOLJET SJ-1045 grand format printer. Roland specialty inks include the

industry’s first white eco-solvent ink, available as an option for the

SOLJET SC-545EX.

The Roland media lineup includes more than 50 products

that have been strategically selected to meet the needs of the company’s

diverse customer base in the sign, vehicle graphics, fine art and photography

industries. All Roland media products are profiled for performance with the

company’s inkjet technologies including VersaCAMM, SOLJET and Hi-Fi JET

printers and integrated printer/cutters.

Roland DGA Corporation

Roland DGA Corporation and affiliated companies are

pioneers in the development of innovative digital technology for creative

professionals. From its inception as part of world-renowned Roland Music, Roland

DGA Corp. has introduced an award-winning product line that continues to set new

standards for precision, reliability and performance. Professionals worldwide

rely on Roland equipment and personnel everyday in the sign, graphic arts, fine

art, photography, engraving and 3D modeling industries.

Headquartered in Irvine, California, Roland DGA Corp.

serves as the U.S.-based marketing, distribution and sales arm of Roland DG

Corporation of Hamamatsu, Japan. Affiliated companies include Roland US and

Roland Audio in Los Angeles, CA; Rodgers Instrument Corporation of Hillsboro,

OR; and Edirol Corporation of Seattle, WA. Roland DG Corporation is listed on

the Tokyo Stock Exchange.

Roland DGA is ISO 9001:2000 certified, and Roland DG

is ISO-9001:2000 and 14001 certified. Roland’s Color Products Division

markets the company’s advanced inkjet technologies in North and South

America (except Brazil) through its Authorized Resellers. Major products include

the SOLJET, VersaCAMM and Hi-Fi JET Pro lines of inkjet printers and

printer/cutters. Roland’s newly-formed Advanced Solutions Division is

responsible for marketing the company’s complete line of vinyl cutters,

engravers, 3D scanning and milling devices, and a photo impact

printer.

For more information, please call (800) 542-2307 or

visit the Web site at http://www.rolanddga.com.

Posted: Fri - August 26, 2005 at 04:37 PM WIR NewsStream by Piranha Daily News The Stream Previous Next

Quick Links

Calendar

| October 2005 | ||||||

| Sun | Mon | Tue | Wed | Thu | Fri | Sat |

| 1 | ||||||

| 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| 16 | 17 | 18 | 19 | 20 | 21 | 22 |

| 23 | 24 | 25 | 26 | 27 | 28 | 29 |

| 30 | 31 | |||||

Categories

Search

Archives

XML/RSS Feed

Piranha Daily News

Statistics

Total entries in this blog: 1561

Total entries in this category: 1561

Published On: Sep 13, 2005 07:22 PM

Total entries in this category: 1561

Published On: Sep 13, 2005 07:22 PM